Milestones at Barth Schleiftechnik

1964

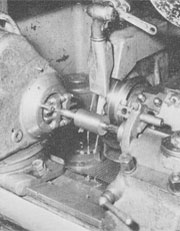

Way back in 1964, Ernst Barth established a small tool grinding business, working from the cellar of his home. He borrowed DM 20,000 from his mother to buy a Deckel S1 tool grinder, which allowed him to start up the business. At the outset, he worked on his own, but he quickly saw that he would need help, so his wife, Gertrud, started to work on the machine with him.

1988

In 1988, Ernst Barth joined forces with other tool-grinding colleagues to establish the Fachverband Deutscher Präzisionsschleifer (German Precision-Grinding Association), and was active as a member of its Board for many years. In this role in the FDPW, he helped to prepare the way for GRIND-TEC in Augsburg, the world’s leading grinding technology trade fair that was held for the first time in 1998.

1989

The company moved to new production premises (some 400 m2) in Eisackstraße in 1989.

1990

In 1990, the company passed into the hands of Michael Barth - the founder's son - after he had completed his toolmaker’s training. The company invested in its first CNC machines at the same time. After a six-month stay in the USA on a programming course for grinding machinery and after “special training” from his father, Michael Barth achieved the title of Master Cutting Tool Mechanic in 1993 – making him the first, the youngest and the only person to hold this title in Germany.

1995

In 1995, he took over the company from his father. By now it had grown to 12 people. There was further investment in CNC grinders and production was extended into another basement.

1998

Introducing our webseite www.schleiftechnik.com.

2000

In 2000, the Ernst Barth Werkzeugschleiferei became Barth Schleiftechnik GmbH.

2004

An ISO 9001 quality management system was introduced in 2004.

2006

After further extending the production facilities to 1200 m2 and totally renovating the premises in 2006. Barth Schleiftechnik introduced an automatic loading system for two Deckel S22 CNC machines to set up the unmanned “ghost shift”. This is monitored remotely over the Internet using a number of cameras.

2009

In 2009 BARTH Schleiftechnik began production of standard solid carbide milling cutters and since then has produced high quality, good value DIN solid carbide tools. At the same time an extensive warehouse was built to enable immediate availability of supply, and the first catalogue was compiled. Incidentally, all BARTH solid carbide milling cutters and drills are produced by the company at its Augsburg site.

2012

Development of the opposing flute helix solid carbide milling cutter ConVecut. With registered trademark and patent application submitted to the Germany and European Patent Office.

2016

Modification and extension of production for solid carbide tools with additional measuring machines, CNC tool grinding machines, laser inscription and dressing machines.

2018

Renewal of a system for cutting edge preparation in drag grinding and expansion of the measurement options for the cutting edge rounding of <0.002 mm.

2019

Commissioning of another 5-axis CNC tool grinding machine for grinding solid carbide drills. Replacement and renewal of a grinding machine for grinding large HSS drills up to diameter 80 mm.

2020

Expansion of production with a CNC surface grinding machine for surface grinding of high-precision machine components.